EM-ISight Automated ESD Scanner

Electrostatic discharge (ESD) events can lead to failures in electronic components and systems, such as short circuits and combustion, posing significant risks to device reliability and safety.

The APREL EM-ISight-ESD system offers manufacturers a powerful solution to identify design flaws and enhance product performance and safety prior to market release.

Utilizing advanced measurement methodologies, the system captures ESD events across spatial locations and resolves time and frequency domain data through high-bandwidth oscilloscopes. By integrating multiple measurement functions into a single capture, the EM-ISight-ESD system transforms how EMC engineers perform ESD analysis.

Engineered to support a broad range of testing applications, the ESD scanner delivers unparalleled capabilities for near-field analysis.

Features:

-

Time domain of an ESD event

-

Frequency domain of an ESD event

-

Spatial data of an ESD event

-

Visualization in either time or frequency through AVI movie

-

Dynamic touch detection and vision control

-

Compatibility with Oscilloscope, Spectrum Analyzer, Vector Network Analyzer

“Leveraging APREL's EM-ISight-ESD solution enabled us to resolve a critical design issue related to dropped data packets. During validation for a major customer, we encountered several challenges that raised concerns among the approval team. Using the EM-ISight-ESD solution, we assessed the impact of ESD signals across the frequency range, uncovering a minor design flaw that we quickly addressed—ultimately securing customer approval.

Without this solution, we would have faced a costly and disruptive redesign of our entire board, significantly impacting our project."

Program manager, automotive solutions

SYSTEM ELEMENTS AND CONFIGURATIONS

-

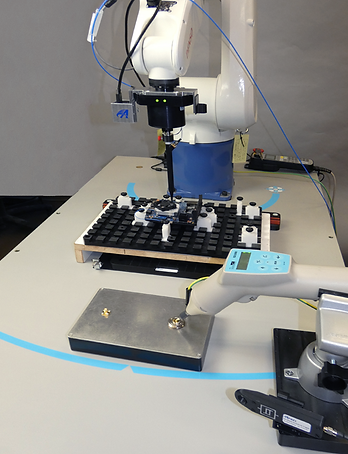

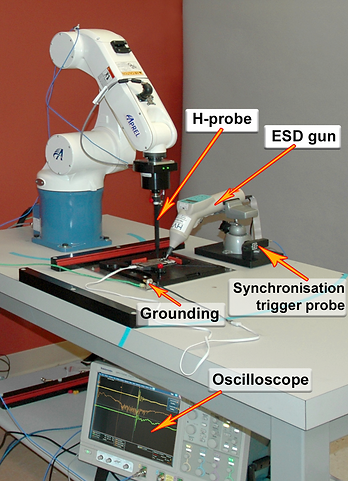

The EM-ISight-ESD is a fully integrated test system designed to measure test subjects exposed to an electrostatic discharge (ESD) source. As an industry-first solution, it enables real-time measurement of ESD events across frequency, time, and spatial distribution.

-

It provides users with confidence in the accuracy and reliability of high-speed ESD event detection, helping to identify vulnerabilities that can lead to device damage.

-

Synchronization of the ESD event with data acquisition is achieved through the use of a broadband trigger probe. This ensures the ESD event is captured from its initiation and recorded continuously throughout its duration, up to the point of signal dissipation.

-

EM-ISight-ESD is a complete package including standard Near-Field measurement options in one fully automated system.

-

APREL offer the option for further system customization.

System Components:

-

6-axis robot arm

-

System controller running WinPro

-

Workstation

-

Boundary detection unit (BDU)

-

ESD H-field probe

-

Trigger synchronization probe

-

Vector probes

-

magnetic 2mm-loop Hxy

-

optional electric Exy and Ez

-

SMA connector

-

-

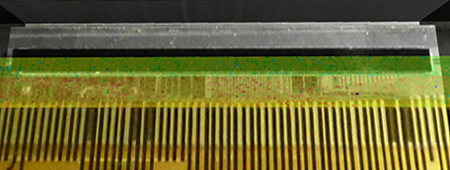

ESD microstrip line

-

6GHz microstrip line

-

Low noise amplifier (LNA)

-

Device positioner

-

Set of cables

-

Vision system

Applications:

-

Automotive, LCD/OLED panels and televisions, industrial appliances, home appliances, avionics, radar systems, computers and communication devices, medical devices, medium scale network equipment, routers, switches, and base stations.

Oscilloscope readings

System validation setup